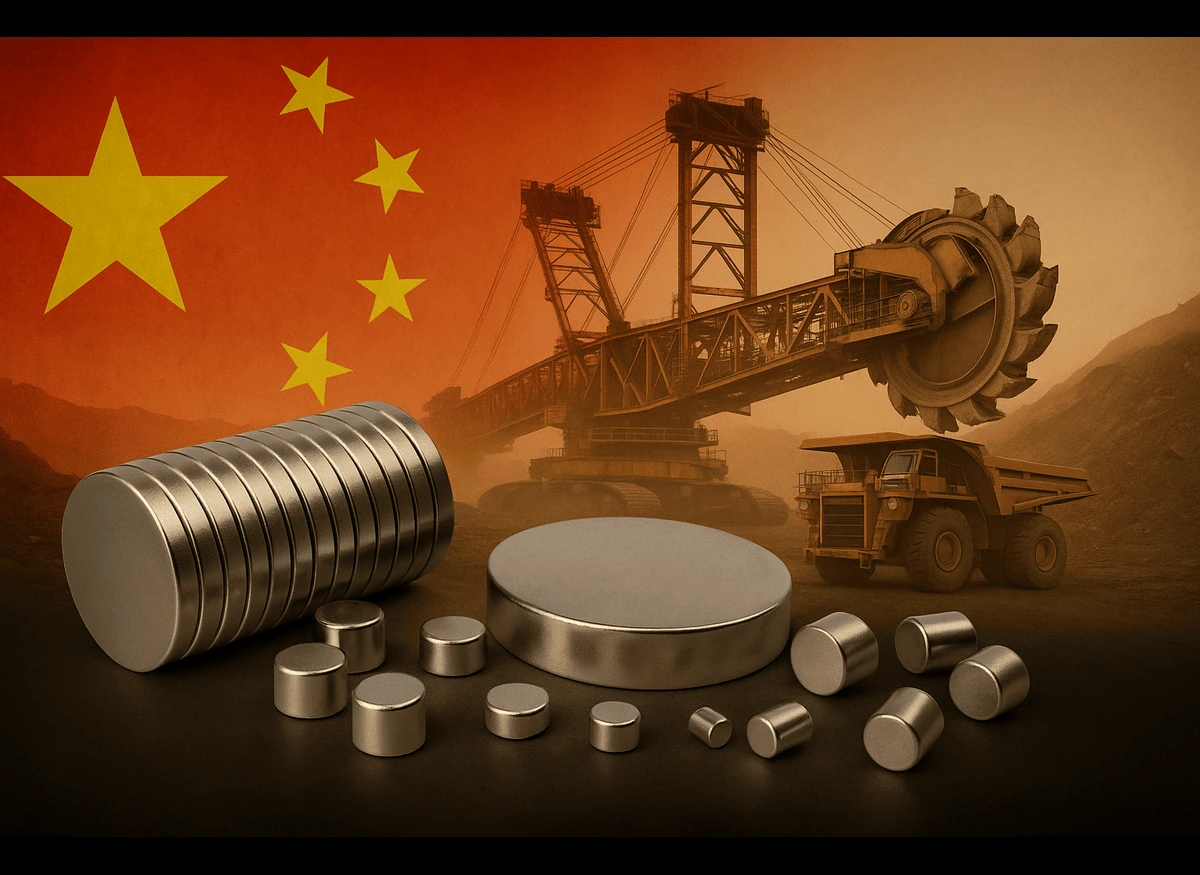

China’s April 2025 export controls on rare earths and NdFeB magnets have rattled global industries—from EVs to defense—exposing supply chain fragility. With India and the world looking for alternatives, the crisis highlights urgent needs for diversification, refining, and recycling.

On April 4, 2025, China implemented stringent export controls on rare earth elements (REEs) and neodymium-iron-boron (NdFeB) magnets, disrupting global supply chains critical to electronics, automotive manufacturing, renewable energy, and defense industries. These restrictions, driven by China’s dominance in REE production and escalating geopolitical tensions, particularly with the United States, have caused immediate shortages, price spikes, and production delays. With China controlling 60% of global REE mining, 85% of refining, and 90% of NdFeB magnet production, the policy has exposed vulnerabilities in concentrated supply chains.

Understanding Rare Earth Elements and NdFeB Magnets

Rare earth elements (REEs) are a group of 17 chemically similar elements, including 15 lanthanides (e.g., lanthanum, cerium, neodymium, praseodymium, dysprosium, terbium, gadolinium, samarium, lutetium), plus scandium and yttrium. These elements possess unique magnetic, luminescent, and catalytic properties, making them essential for advanced technologies. While REEs are not geologically rare—global reserves exceed 120 million metric tons—their extraction and refining are complex, energy-intensive, and environmentally challenging due to low-concentration ores (typically 0.5-2% REE content) and radioactive byproducts like thorium.

The primary application of REEs is in NdFeB magnets, the strongest permanent magnets available, with a magnetic flux density of 1.2-1.4 Tesla and coercivity (resistance to demagnetization) of 10-30 kOe. These magnets typically consist of:

Neodymium (Nd): 27-32% by weight, providing high magnetic strength.

Dysprosium (Dy) or Terbium (Tb): 0.5-4%, enhancing thermal stability for applications up to 200°C.

Praseodymium (Pr): 5-10%, often substituted for neodymium to reduce costs.

Iron (Fe): 60-65%, forming the magnetic alloy’s structure.

Boron (B): 1-2%, stabilizing the crystal lattice.

NdFeB magnets are manufactured through a multi-step process:

Mining and Refining: REE ores are crushed, milled, and processed via flotation, followed by solvent extraction to produce 99% pure REE oxides. These are reduced to metals using electrolysis.

Alloy Production: Neodymium, dysprosium, and iron are melted into ingots via strip casting.

Magnet Fabrication: Ingots are pulverized, pressed into shapes under a magnetic field, sintered at 1000°C, and coated to prevent corrosion.

NdFeB magnets are critical for:

Electronics: Micro-magnets (0.1-0.5 g) in smartphone speakers, haptic motors, and camera autofocus systems; 1-2 g in laptop hard drives.

Electric Vehicles (EVs): 1-2 kg per permanent magnet synchronous motor (PMSM), delivering torque density of 5-10 Nm/kg.

Wind Turbines: 600-700 kg per megawatt in direct-drive generators, enabling 90% efficiency.

Defense: 500-600 kg in fighter jets (e.g., F-35 actuators) and 50-100 g in missile guidance systems.

Industrial Automation: 50-100 g per servo motor in robotics, ensuring precision and durability.

China produces 150,000 metric tons of NdFeB magnets annually (90% of global supply), supported by 140,000 tons of REE mining (60% of global total) and 85% of refining capacity, leveraging economies of scale and relaxed environmental standards.

China’s Export Controls: Policy and Technical Details

On April 4, 2025, China’s Ministry of Commerce (MOFCOM) and General Administration of Customs issued Announcement 18, imposing export controls on six medium and heavy REEs (samarium, gadolinium, dysprosium, terbium, lutetium, scandium), yttrium, and NdFeB magnets. The policy includes:

Export Licensing: Exporters must obtain MOFCOM licenses, requiring detailed end-use and end-user data, with processing times of 6 weeks to 4 months. Over 70% of applications were pending as of May 2025, causing port delays.

Technology Bans: Exports of REE refining technologies (e.g., solvent extraction, ion exchange) and magnet production processes (e.g., hydrogen decrepitation, sintering) are prohibited, blocking foreign access to China’s expertise.

Joint Venture Oversight: Foreign partnerships involving REE processing or magnet manufacturing face rigorous scrutiny, halting most technology transfers.

The controls were framed as protecting national security and intellectual property, but they align with China’s response to U.S. tariffs, which rose to 54% on Chinese goods in April 2025 following President Trump’s trade policies. The restrictions extend earlier bans on gallium, germanium, and graphite exports to the U.S. in December 2024, reflecting China’s strategic use of critical minerals.

Immediate Technical Impacts on Industries

The export controls triggered a 51% year-on-year drop in NdFeB magnet exports (from 5,400 tons in April 2024 to 2,626 tons in April 2025) and a 16% decline in REE exports (from 5,600 tons in March to 4,785 tons in April 2025). This has disrupted industries reliant on precise magnet specifications and just-in-time inventories.

Electronics

NdFeB magnets enable compact, high-performance components in consumer electronics:

Smartphones: Each device uses 0.1-0.5 g of magnets (0.03-0.15 g neodymium, 0.001-0.01 g dysprosium) for speakers, haptic motors, and autofocus lenses. An iPhone 15 contains 0.3 g of magnets.

Laptops and Tablets: Hard drives require 1-2 g of magnets; cooling fans use 0.5-1 g.

Impact: The export drop depleted magnet stocks to 2-4 weeks by May 2025, with manufacturers like Foxconn holding 500 tons globally. Magnet prices rose 30% (from $50/kg to $65/kg), adding $150 million to Apple’s 2025 iPhone production costs. Samsung reported a 10% production delay risk for Q3 2025 due to shortages.

Automotive Industry

EVs rely on PMSMs, which use 1-2 kg of NdFeB magnets per motor (0.3-0.6 kg neodymium, 0.02-0.05 kg dysprosium) for 90-95% efficiency and 5-10 Nm/kg torque density. Dysprosium ensures thermal stability at 150-200°C.

Impact: India imported 460 tons of magnets in FY24 ($20 million), with 2025 demand projected at 700 tons ($30 million). Stocks fell to 50-100 tons (2-3 weeks) by May 2025, threatening production halts for Tata Motors’ Nexon EV and Mahindra’s XUV400. Magnet cost increases could raise EV motor prices by 5-7% ($1,200 to $1,300 per motor). Globally, Toyota’s Kentucky plant lost $10 million from a three-day halt in May 2025.

Renewable Energy

Direct-drive wind turbines use 600-700 kg of magnets per megawatt (180-200 kg neodymium, 10-20 kg dysprosium). Lithium-ion batteries use lanthanum (1-2 kg per EV battery) for cathode stability.

Impact: Magnet shortages threaten 10 GW of wind capacity additions in Europe and the U.S. for 2025-2026. Turbine costs could rise 5-10% ($50,000-$100,000 per MW), delaying decarbonization goals.

Defense

NdFeB magnets are critical for military systems:

Fighter Jets: F-35 jets use 500-600 kg of magnets for actuators and radar.

Missiles: Guidance systems require 50-100 g of magnets with coercivity above 20 kOe.

Impact: U.S. defense contractors face 120-day lead times for magnets (up from 60 days), risking delays in F-35 production (200 jets annually) and missile stockpiling. China supplies 80% of U.S. magnet imports.

Regional Focus: India’s Technical Challenges

India currently imports nearly 90% of its neodymium-iron-boron (NdFeB) magnets from China, leaving the country highly vulnerable to external shocks, with no domestic production capacity for magnet-grade rare earth elements (REEs). This dependency has exposed Indian industry to acute supply risks following China’s April 2025 export restrictions.

- In the automotive sector, India’s electric vehicle (EV) transition is especially at risk. Permanent magnet synchronous motors (PMSMs)—used in nearly all modern EVs for their high torque-to-weight ratio—require 1–2 kg of NdFeB magnets per motor. With projected EV penetration reaching 30% of total vehicle sales by 2030, India’s demand for magnets is rising sharply. Industry estimates suggest that national stocks fell to just 50–100 tons by May 2025, covering only 2–3 weeks of EV production. The Society of Indian Automobile Manufacturers (SIAM) has warned that over 80% of current magnet stock is reserved for traction motors and advanced sensors. Automakers like Tata Motors and Mahindra are already facing potential production slowdowns in Q3 2025, with cost projections rising by 5–7% per motor due to elevated magnet prices.

- In the electronics sector, India’s large-scale mobile phone manufacturing—driven by companies like Xiaomi, Samsung, and Apple’s contract partners—is also at risk. A typical smartphone contains 0.1–0.5 grams of magnets for speakers, haptics, and camera autofocus. With India producing over 300 million smartphones annually, even marginal price increases in magnets (which rose from $50/kg to $65/kg) could raise total production costs by hundreds of crores. For instance, Xiaomi’s 50-million-unit annual output in India could face a 2–3% average cost hike due to magnet shortages alone.

From a policy standpoint, India’s response is still in early stages. The Ministry of Mines launched the Critical Minerals Mission, aiming to diversify REE sourcing and reduce strategic dependence on China. A key initiative involves securing long-term partnerships with companies like Australia’s Lynas Corporation, which currently produces over 15,000 tons of REE oxides annually. Domestically, state-owned IREL (India) Limited is ramping up operations at its Rare Earth Extraction Plant in Odisha. While the facility targets 5,000 tons of REE oxide capacity by 2028, its current output remains under 1,000 tons, insufficient for immediate industry needs. Furthermore, the Geological Survey of India (GSI) has identified approximately 13 million tons of REE deposits, particularly monazite-rich sands in coastal regions like Andhra Pradesh and Tamil Nadu. However, the lack of refining infrastructure—especially solvent extraction and metallurgical separation plants—continues to be the main bottleneck.

India’s path forward will require a multi-pronged approach: accelerated exploration, faster environmental clearances, public-private investment in REE refining, and strategic stockpiling to buffer against future geopolitical shocks.

Global Supply Chain Vulnerabilities

China’s dominance exposes technical weaknesses:

Mining and Refining: China processes 85% of global REE oxides (120,000 tons in 2024) using solvent extraction (99% purity) and electrolysis. Competitors like Lynas (15,000 tons) and MP Materials (5,000 tons) lack scale.

Magnet Production: China’s 150,000-ton NdFeB capacity dwarfs Japan (10,000 tons) and Europe (5,000 tons). Non-Chinese manufacturers rely on Chinese REE inputs.

Environmental Barriers: Refining produces 1-2 tons of toxic waste per ton of oxide, deterring new facilities in the EU and U.S.

The 2010 Japan embargo, which cut REE exports 40%, raised magnet prices 200% and disrupted industries for two years, underscoring the current crisis’s severity.

Strategic Responses and Technical Mitigation

Governments and industries are addressing the crisis:

United States:

Domestic Production: MP Materials’ Texas facility targets 1,000 tons of NdFeB magnets by late 2025, using 5,000 tons of REE oxides. The DOD’s $44.6 million investment supports refining upgrades.

Recycling: Phoenix Tailings aims for 4,000 tons of recycled REEs by 2027, using hydrometallurgical processes.

Europe:

Critical Raw Materials Act: Targets 10% domestic REE sourcing by 2030, with LKAB’s Per Geijer mine (500,000 tons of REEs).

Industry Dialogues: In May 2025, European firms like Volkswagen secured limited magnet licenses from China.

India:

Diplomacy: SIAM and ACMA planned a June 2025 delegation to China to release 200 tons of magnet shipments.

Exploration: Domestic REE projects are underway, but commercial refining is 5-7 years away.

Global Efforts:

Diversification: Japan’s investment in Lynas reduced its Chinese REE reliance to 50% by 2025.

Stockpiling: The U.S. and Japan hold 1,000-2,000 tons of REE oxides (3-6 months of demand).

Long-Term Outlook

By 2027, alternative supply chains may ease shortages:

New Sources: Australia’s Iluka Resources and Brazil’s Serra Verde could add 10,000 tons of REE oxides annually.

Recycling: Global recycling could supply 5-10% of REE demand by 2030.

Innovation: REE-free motors (e.g., switched reluctance motors) are under development but offer lower efficiency (85-90%).

Building new refining and magnet facilities requires 10-15 years and $500 million-$1 billion, limiting short-term relief.

China’s export controls on REEs and NdFeB magnets, causing a 51% drop in magnet exports and 16% in REEs, have disrupted global supply chains. India’s 50-100 tons of magnet stocks risk production halts for EVs and electronics, while global industries face cost spikes and delays. China’s 90% control of NdFeB production underscores the need for diversified supply chains, domestic refining, and recycling. While immediate challenges persist through 2025, investments in alternative sources and technologies signal progress toward resilience by 2027, though consumers and industries must brace for higher costs and supply constraints in the interim.

Also Read: U.S. President’s 25% Automotive Tariffs

Discover more from Poniak Times

Subscribe to get the latest posts sent to your email.